Description

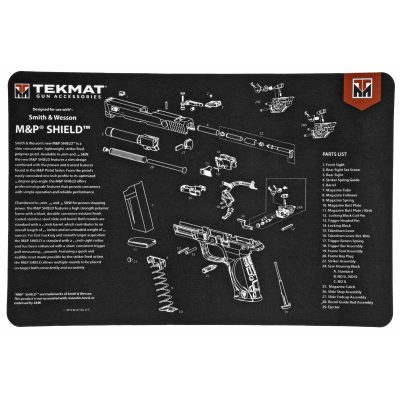

Our Gunsmith Thread Securement Kit comes with necessary grease and thread lockers used when assembling AR15’s, AR-10’s and well as other rifles and firearms, or when swapping parts. Each chemical in the kit is in a capped syringe for easy application. We understand there isn’t one chemical that works for all applications, which is why a kit such as this is useful. Using the right chemical in the right application ensures the firearm is built correctly the first time.

The idea for the Gunsmith Thread Securement Kit came from working alongside licensed gun smith and observing the tools and chemicals utilized while completing a build. The syringes were chosen due to their versatility and compact storage, as well as the convenience and ease when applying grease and thread lockers.

Each kit contains enough of each type of chemical to complete up to 20 or more AR-15 or AR-10 builds depending on the amount of chemical used per build.

The Gunsmith Thread Securement Kit helps in saving money by preventing the purchase of multiple bottles of various expensive chemicals that expire before they can be used. The Gunsmith Thread Securement Kit will have just the right amount of chemical for the beginner or experienced gunsmith or armorer. Thread lockers are typically good for approximately one year after the seal is broken. Save money and avoid purchasing large amounts of chemicals that will likely go bad before you can use it up.

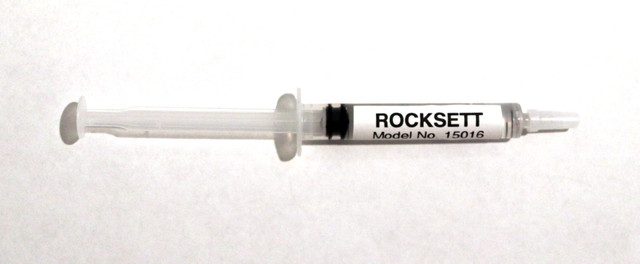

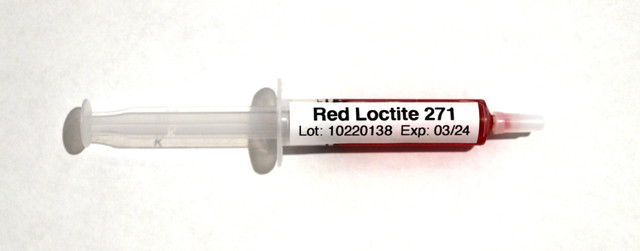

The Gunsmith Thread Securement Kit includes 3ml of Aeroshell 64 grease, 3ml of Rocksett (ceramic high temp adhesive for muzzle devices), 3ml of Loctite 271 (red, high strength), 3ml of Loctite 242 (blue, medium strength), 3ml of Loctite 222MS (purple/pink, low strength), and 3ml of Loctite 620 (green, retaining compound). The kit also included 100 pack of swabs for further ease with application of cleaning excess chemical after application.

Instruction and caution:

The 3ml of Loctite are packaged in 5 ml syringes and 2ml of air. The chemical is packaged in this manner to prevent the Loctite from curing in the absence of air. The air in the tube is critical to keeping the Loctite from curing. It is important to keep a minimum of 2ml of air in the Loctite tubes at all times to maintain the optimum life span. Additionally, the extra air allows for shaking the lower viscosity Loctite like 242 and 222MS which separates over time.

Each Loctite expires 1 year from your purchase date, however; each tube is marked with the individual expiration date. It is recommended to check each chemical for signs of it going bad before use.

The use of gloves is strongly recommended when applying any chemical as well as having swabs or rags within reach. Some chemicals may have negative health effects if used inappropriately. Use chemicals responsibly and consult the documentation (listed below) if you have any concerns. Again, the use of nitrile gloves is strongly recommended as well as thoroughly washing hands after using any chemical and/or handling dirty guns. Use all chemicals in a well ventilated area.

Gunsmith Thread Securement Kit contents and use:

Aeroshell 64 grease (grey) – Standard moly grease used by professional armorers and is generally accepted as the best grease for use on the AR-15. It is used for any threaded assembly where a thread locker is not a better fit. Assemblies that have their own locking mechanism such as staking or anti rotation tabs like barrel nuts and castle nuts are the most common application.

The grease component lubricates the threads during assembly allowing you to achieve a “wet torque”. This provides more clamping pressure for a given amount of applied torque. The grease also helps prevent damage to the threads from galling. The molybdenum disulfide additive is a dry lubricant that remains in place even after the liquid component of the grease has dried or baked off from heat and allows for easier disassembly.

A liberal application is typically used and can be brushed on or smeared with your finger. Wipe off excess with a swab or rag. The syringe allows you to apply just the right amount so there is usually very little waste and the small tube can be stretched over several builds.

Aeroshell 64 is also handy for holding small springs in place temporarily and for assisting in driving roll pins.

Flexbar Rocksett ceramic adhesive/cement (clear) – Rocksett is a ceramic adhesive that features an extremely high temperature rating of 2,105F. It is used primarily for suppressor mounts since it will not deteriorate from use with a suppressor since the ceramic is water based. It is also often used with gas block set screws although red Loctite (271 or 272) is typically used for this. For removal the most common method is soaking the assembly in water for 24 hours or in boiling water for 15 minutes to soften it. A brass hammer may also be used to strike a steel assembly to shatter the adhesive. Caution should be used if a brass hammer is used for this task.

On suppressor mounts, use an amount roughly the size of a pea on the male thread toward the end. The muzzle device will coat the rest of the thread as it is installed. Overuse can increase cure times so be sure not to overdo it. Normal cure time is 24 hours so do not shoot the gun during that window. You can also “heat cure” the muzzle device by holding it over a heat gun at low temperature (150-200F) for 15 minutes. This drives out the moisture and can cure the Rocksett faster.

Rocksett can go bad over time so discard it when the liquid starts to turn yellow instead of clear or thickens up (sort of like honey). The tip of the syringe may dry out with repeated use as well so use a needle or small pick to clear the tip and purge a small amount onto a rag.

Loctite 271 (Translucent Red, High Strength) – The go to securement chemical for gas block set screws. A high strength thread locker with high heat resistance and used reliably by many firearm manufacturers for years. Prior to the use of Loctite, it is recommended to degrease the threads with acetone or denatured alcohol.

To remove the Loctite, heat the assembly to approximately 350F is required to break free. A heat gun or torch is generally used for this.

Loctite 242 (Blue, Medium Strength) – Loctite 242 is the general-purpose thread locker on the AR-15. It works great for most fasteners on rails, MLOK nuts, and more. Only mild heat (150F) is needed for removal on smaller fasteners but usually it will break free without. If you are working with a stripped fastener its probably worth adding some heat out of an abundance of caution.

Prior to the use of Loctite, it is recommended to degrease the threads with acetone or denatured alcohol. Due to its lower viscosity, shake well prior to each use.

Loctite 222MS (Pink/Purple, Low Strength) – Loctite 222MS is a low strength thread locker for use with sensitive applications and tiny screws. It usually does not require any head for removal and is often “just enough” to keep a fastener from coming loose. 222MS is best suited for small optic screws or the dogleg screws that come with Aero Precision M4E1 and other receivers. It is also called out specifically for use on the set screws in Wedge Lock handguards and the cross bolt in Pinch Lock handguards.

While 222MS is most appropriate for small fasteners, be sure not to over torque them during install. Use good quality tools and even a small amount of heat if there’s any chance of stripping a fastener.

Prior to the use of Loctite, it is recommended to degrease the threads with acetone or denatured alcohol. Due to its lower viscosity, shake well prior to each use.

Loctite 620 (Green, Retaining Compound) – Loctite 620 is a nice addition to the pro level Armorer Chem Kit for advanced users. It is a retaining compound used for sleeving and bedding applications. It can make up for sloppy fitting assemblies like barrels in receivers and is good up to a .005″ gap. Caution should be used with 620 as its easy to get things stuck so it should only be used if you are confident in your abilities. This Loctite is not for use on threads!

For installation, degrease each mating surface and wipe a small amount on each one. Be careful not to get it in places where you can’t wipe it up. Apply a thicker coating of 620 to one of the mating surfaces and push the parts together. Wipe up any excess immediately and place the assembly in a position where the liquid can’t run out. You may also apply 100-150F heat for 10-15 minutes to allow the joint to cure faster.

For removal, apply 3-400F heat to the assembly and press the part out. Often times you may hear a small “crack” as the surfaces de-bond. Good fixturing and even heat is key. Soak parts in acetone to soften hardened residue, however mechanical removal may be necessary so keep that in mind before applying it to anything.

6″ Swabs – A very useful tool in the shop, used in application and clean-up of various fluids. Great for heavy application, spreading, and cleaning up excess chemical, as well as using the wooden end for detailed application of various chemicals and products in small areas.

WARNING: This Product Can Expose You to Chemicals Including Lead, which is Known to the State of California to Cause Cancer and Birth Defects or Other Reproductive Harm. For More Information go to www.P65Warnings.ca.gov.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.